Projects - Solar Thermal Collector

A small project following my pre-university internship at an aluminium stamping plant

What was the project about?

After finishing high-school and completing the nine month of mandatory military service I decided to use some of my savings to build a solar thermal collector to heat the family pool. The motivation for this project was quite simple. Heating the family pool during spring and autumn would result in a much longer period in which the water temparature would be acceptable. As many projects, there is a certainlearnign curve here that I will try to illustrate in the following paragraphs.

A first trial with cheap pvc piping, meant for underground cable protection, failed, since it was impossible to achieve a tight seal for the connectors between the tubes. Under direct sunlight the temperature differences induced by the cold water and the high pressure would lead to leaks that could not be contained for long. Even the best glue was no help. Furthermore, plastic is not a good heat conductor and so, while being cost effective, this trial did not yield an optimal solution. (I learned however that curiosity and the drive to do something does not justify to flood the gazebo)

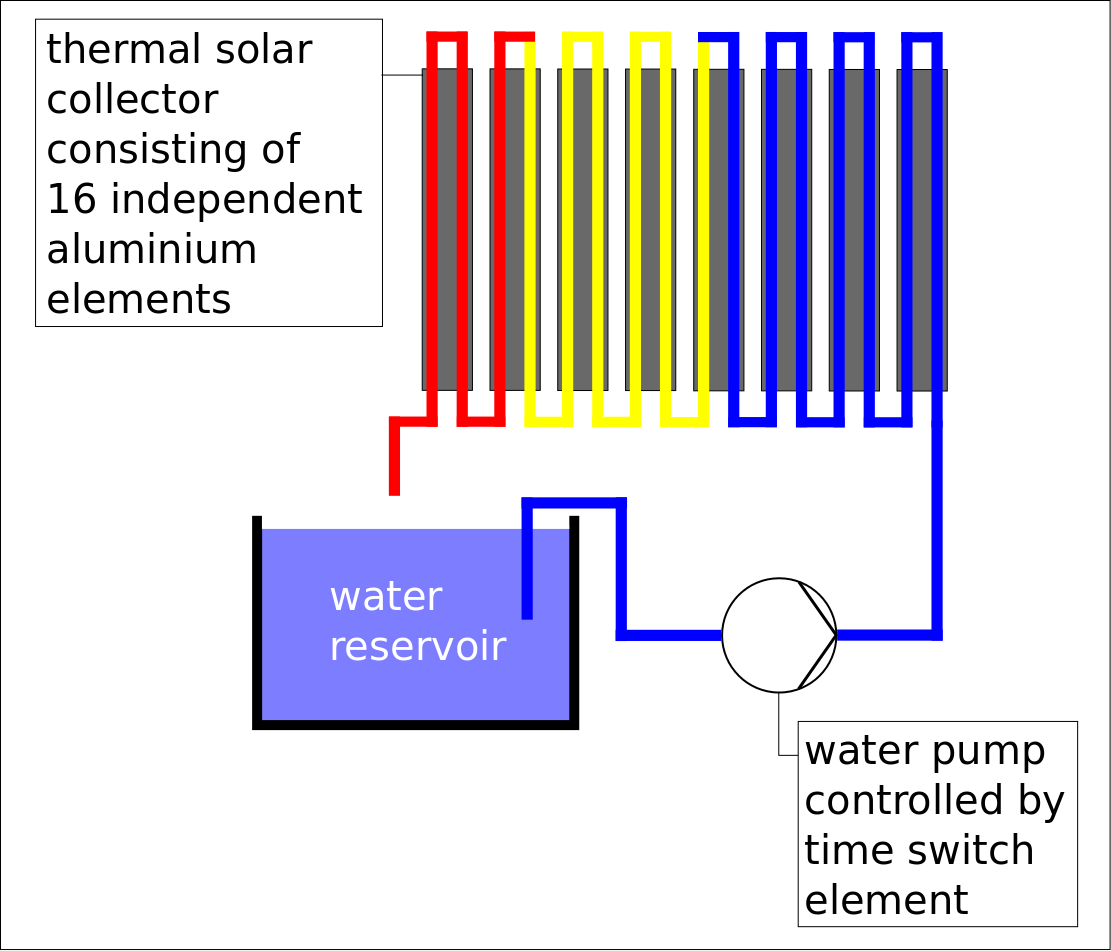

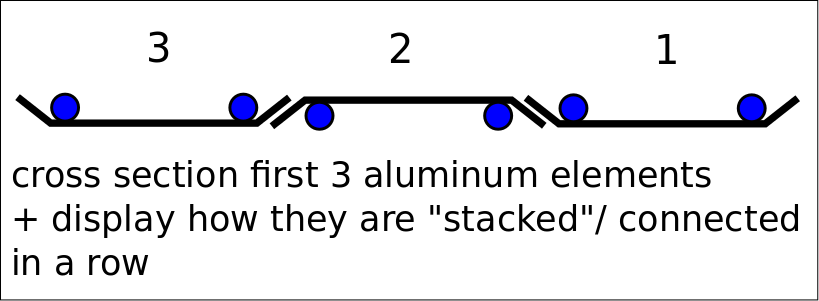

The second trial was a success. Instead of using the cheap pvc piping I opted for aluminum/aluminium - panels. Those panels had a shape (see pictures below) that made it easy to stack them in a row to increase the rigidity of the construction and also increase the effective surface per square meter and weight. For the connection between the panels (a weak point in my previous endeavor) I used special gardening piping connectors that can withstand high pressure and can be left in direct sunlight without leaking over time.

The final version of the of the solar thermal collector consisted of 16 panels and their connectors, a water pump (800 Watts/ ~40m static head) and additional piping leading from the pool to the pump and back from the panels into the pool. Later a time switch element was added to reduce the time the water pump hat to run. It was set up to switch the pump on for a 5 minute interval (enough time to get a full water exchange in the panels) and then wait for 30 minutes to repeat the cycle. Future plans were to replace the time switch with a series of temperature elements on key positions on the solar panel rig in order to have a more robust/reliable solution for cloudy days.

Project information

- Category engineering

- Project date 2006